Specifications:

- Workpiece outside diameter if 10:1 ratio, mm 500

- Module, mm 10

- Whole depth, mm 22

- Pitch apex to crown if pitch angle 30 degree, mm 250

- Face width, mm 90

- Pitch angle min 5 deg

- Number of teeth 10-200

- Time rate machining per tooth, sec 15-128

- Maximum ratio between wheel pair if pitch angle 90 deg 10:1

- Rocking angle cutting spindle (cradle), deg 4-90

- Angle change between cutters, deg 0-11 with positioning 2'

- Cutter stroke (reciprocating slide), mm 16-100

- Number of cutter double strokes per minute 76-450

- Distance from machine center to the end work spindle , mm

- minimum 60

- maximum 360

- Scale for measurment of installation accuracy the work spindle, mm 0.02

- Diameter of hole through spindle, mm 80

- Cutter spindle motor, kW 5

- Voltage 50 Hz 380/220 Volt

- Machine weight, kg 7900

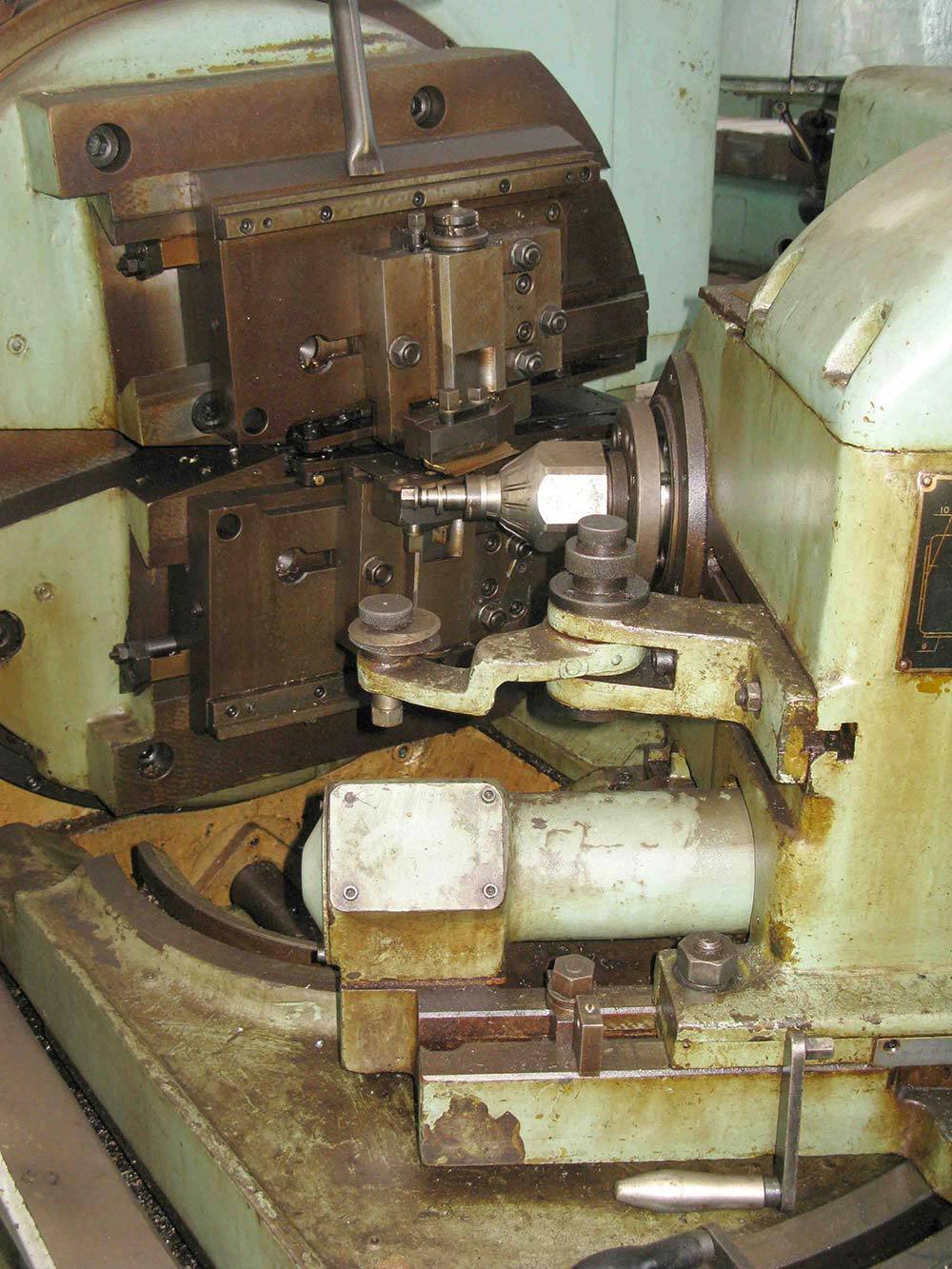

Straight bevel gear generator 5A250P

Workpiece diameter 500 mm x module 10

This machine is designed for cutting gear wheels, tooth processing performed generating method and/or planing with two cutters that move linearly. Types of cut gears - straight bevel gear, screw gear, face gear.

Straight bevel gears have tapered conical teeth which intersect the same tooth geometry. Bevel gears are used to transmit motion between shafts with intersecting center lines. The intersecting angle is normally 90 deg but may be as high as 180 deg. When the mating gears are equal in size and the shafts are positioned at 90 degrees to each other, they are refferred to as miter gears. The teeth of bevel gears can also be cut in a curved manner to produce shape profile of bevel gears, which produce smoother and quieter operation than straight cut bevels.

Face gear are a circular disc with a ring of teeth cut on one side. The gear teeth are tapered toward the center of the tooth. This gears typically mete with a spur gear.

Planing method with two tools that move linearly, while the work either is performing combination of wheel rotations and an additional rotation for flank line (single indexing).

Main > Gear Cutting Machines > Straight bevel gear generator 5A250P